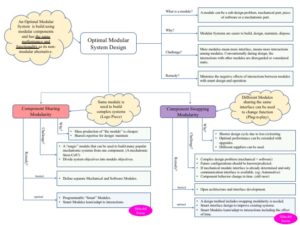

In engineering, building systems from modules is preferred. Modular systems are easier to design, build and maintain. By designing modular systems, cheaper, high-performance products can reach the market faster and operate for a long time with easy maintenance and upgrades. However, compared to the systems that are designed as a whole (concurrent design), modularly designed systems may have inferior performance because when modules are designed individually (sequential design), their interaction with the other modules is generally elided. An Optimal Modular System (OMS) is built using individual designs of its modules and has the same performance and functionality as its concurrently designed alternative.

The development of OMSs presents multiple technical challenges to achieving performance and sustainability benefits simultaneously. Typically, the solution to the modular design problem is a less challenging process as compared to the solution of the concurrent design problem because it uses a subset of the overall design variables, parameters, and formulation for each step. However, since the module is part of the whole system, its optimal design is also affected by the design assumed for the other modules, representing a set of non-changing design parameters in the problem formulation. The optimal solution of the concurrent design problem is considered to be the best solution possible for the modular design problem since it unites all the formulations from all of the modules solved simultaneously for all design variables without presumptions. The performance gap between the concurrent design problem optimal solution and the modular design problem optimal solution can be used to measure the success of modularization. Eliminating this performance gap to achieve optimal modular systems is the primary challenge in our research activities.